Building Services Engineering

RIBA 1-7

Covering all RIBA design stages

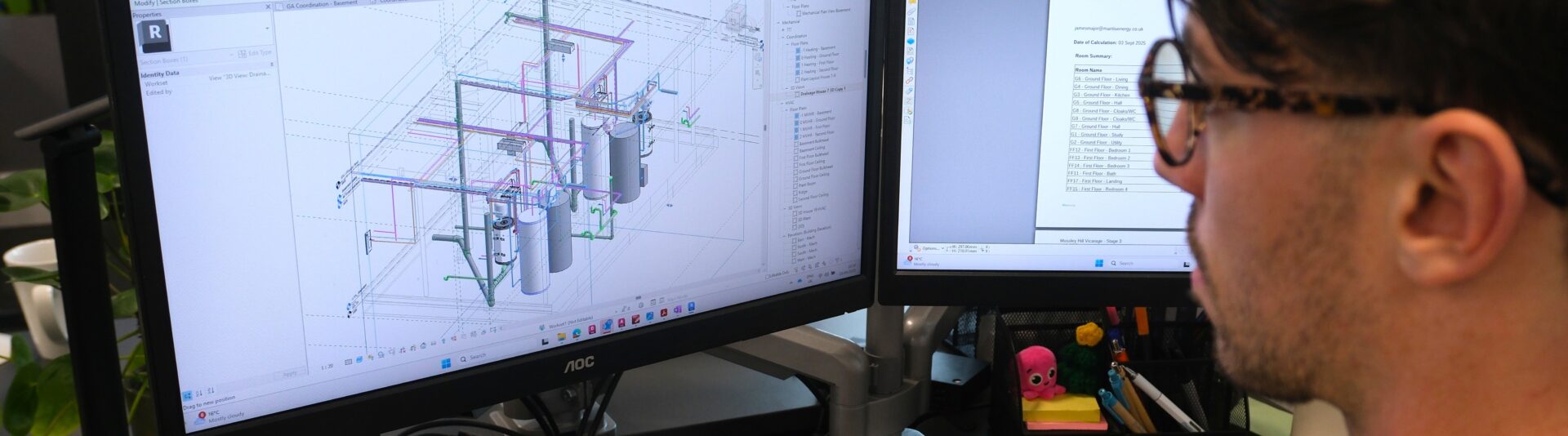

3D REVIT

In house 3D Modelling capability

BIM Ready

Architectural & Structural collaboration

LOD 100-500

Level of Detail (LOD) 100-500 Available

Our experienced building services engineering team can provide mechanical, electrical and public services design for a range of building types.

At Mantis we specialise in efficient and sustainable building services design utilising low carbon heating systems and renewable power generation.

Mechanical Services

-

RIBA Stage 1–7 Services: Developing detailed mechanical designs from initial strategy to technical design and ensuring systems are fully commissioned and monitored through the systems life.

- Site Investigation & Condition Reports: Assessing existing services and determining plant condition typically around the replacement / retrofit of end of life systems.

- Feasibility Assessment and Options Appraisals: Assessing Net Zero Carbon Pathways through Heating, Hot Water, Ventilation and Air Conditioning.

- Mechanical Design Services Covered:

- Air Source Heat Pumps (Air to Air and Air to Water)

- Ground Source Heat Pumps

- Air Conditioning & VRF Heat Recovery Systems

- Mechanical Ventilation Systems including Heat Recovery (MVHR)

- Building Management & HVAC Control Systems

- Mains Cold Water & Boosted Cold Water Systems

- Hot Water Generation Systems

- Hot & Cold Water Distribution

- Sprinkler Systems

- Above Ground Drainage

- Construction Issue and As Built Installation Drawings: during and post construction, access or operation / maintenance purposes.

- Maintenance Reporting and Preventative Maintenance Programmes: Reducing maintenance costs and increasing operational performance.

- Energy and Condition Monitoring: Energy use, verifying carbon savings, identifying and addressing performance issues.

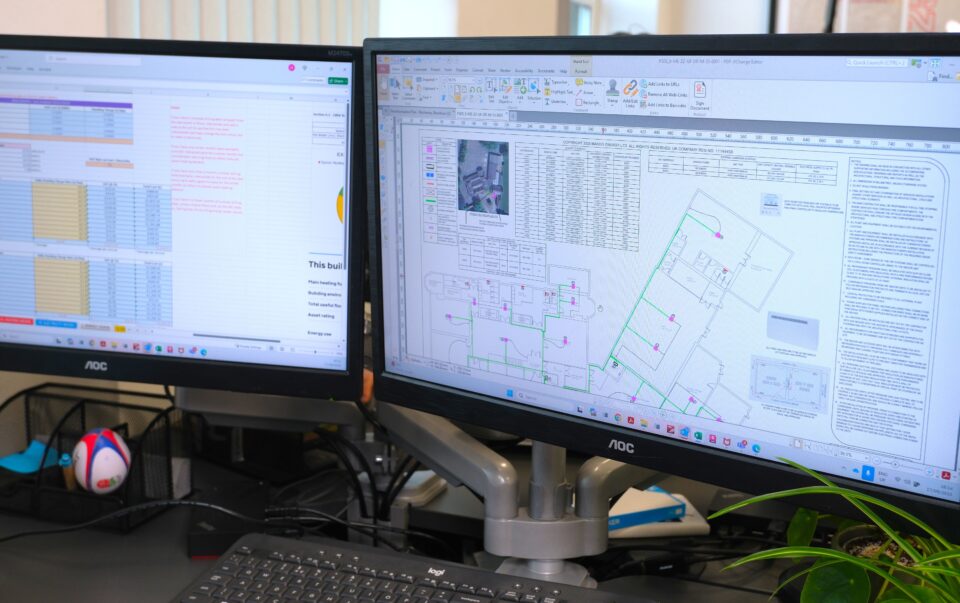

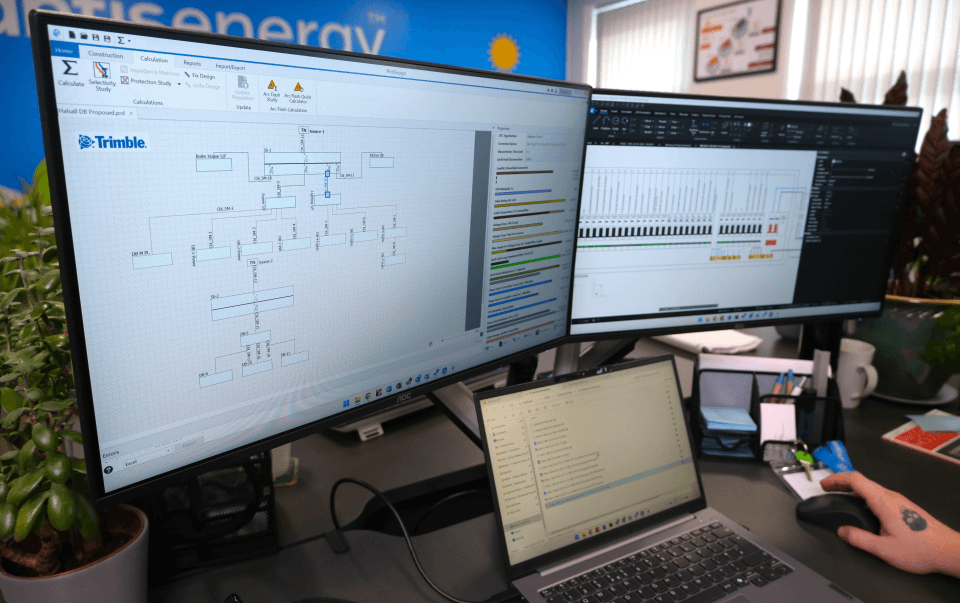

Electrical Design

-

RIBA Stage 1–7 Services: Developing detailed electrical designs from initial strategy to technical design and ensuring systems are sized correctly and energy monitored through system life.

-

Site Investigation & Condition Reports: Assessing existing electrical services and cabling condition typically around the replacement / retrofit of faulty wiring / undersized consumer units.

- Feasibility Assessment and Options Appraisals: Assessing Net Zero Carbon Pathways through energy reduction, electrical infrastructure upgrades and renewable energy

- Electrical Design Services Covered:

- Lighting Design (Internal & External)

- Emergency Lighting Designs

- LV & HV Power & Distribution

- Containment Layouts

- DNO Increased Load / Supply Calculations

- POC Electrical Infrastructure Upgrades

- Earthing & Lightning Protection Systems

- CCTV & Security Systems

- Fire Alarm Designs

- Solar Photovoltaic (PV) Designs

- Battery Storage & UPS System Designs

- Construction Issue and As Built Installation Drawings: during and post construction, access or operation / maintenance purposes.

- Maintenance Reporting and Preventative Maintenance Programmes: Reducing maintenance costs and increasing operational performance.

- Energy and Condition Monitoring: Energy use, verifying carbon savings, identifying and addressing performance issues.

Site Investigation & Condition Reporting

Sometimes we need to understand what has occurred in the past to plan for the future. Its so important to understand the current condition of mechanical and electrical equipment to avoid replacing systems in full working order and also to upgrade systems that will not work with planned retrofit work such as the installation of new low carbon heating systems.

Mechanical Investigations:

- Mechanical Equipment and Plant Room Condition Surveys

- Performance Monitoring of Equipment

- Thermal Imaging Surveys

- Vibration Monitoring

- Flow Testing and Intrusive Access

- Leak Detection and Water Sampling

Electrical Investigations:

- Electrical Equipment and Plant Room Condition Surveys

- Performance Monitoring of Equipment

- PAT Testing

- Voltage, RCD and Earth Continuity Testing

- Peak Load Testing

- Electrical Condition Inspection Report (EICR) Testing

Performance Monitoring and Maintenance

Have a great Mechanical & Electrical design? System installed correctly? Has the system been commissioned and set to perform?

The last step is often overlooked and all the hard work of designing and installing a great low carbon heating system (as an example) can unfold if the system doesn’t perform the way you expect it to. Usually and rightly so the expectation is that a low carbon heating system runs at lower operating cost than its predecessor and provides all heating requirements no matter what the conditions are.

Performance monitoring is so important post installation and often ties in with maintenance requirements. The performance of a system once designed and installed correctly comes down to existing setup and maintenance. Setups can be modified / improved and maintenance can be carried out to improve existing performance.

We deliver clear, practical performance improvement and maintenance recommendations to ensure equipment is always in full working order. From reactive maintenance due to performance issues or preventative maintenance programmes to ensure equipment always runs at peak performance.